Exploring the Manufacturing Challenges for Direct Food Contact Inks – Simon Daplyn, Sun Chemical

We are all increasingly concerned with sustainability and our environmental impact, and the move towards eco-friendly packaging solutions is becoming more important to all of us. At FuturePrint TECH 2023, Simon Daplyn from Sun Chemical spoke about the complexities and innovations surrounding direct food contact inks and the transition towards paper packaging within consumer goods.

Consumer behaviour and expectations have changed significantly, with online shopping becoming a lot more popular and sustainability moving to the top of people’s agenda. Large FMCG brands find themselves in a competitive landscape, not only with each other but also with smaller, innovative startups. The differentiation factor in the competitive landscape means that FMCG brands and smaller, innovative startups are increasingly leaning towards sustainability and environmental consciousness, expressed through packaging design. Packaging, as the first touchpoint with consumers, plays a critical role in reflecting a brand's purpose and values, especially concerning recyclability and environmental impact.

Simon Daplyn also touched on the growing trend among younger consumers: a conscious effort to choose products based on packaging recyclability. This shift in consumer values shows the importance of moving towards more sustainable packaging options, such as paper-based solutions, to align with the environmental awareness and expectations, of younger generations.

The transition to paper-based packaging, whilst beneficial for the environment, throws up several challenges: Maintaining the protective and functional qualities of traditional plastic packaging and adhering to the complex regulations surrounding food contact materials. Sun Chemical, with expertise in manufacturing high-quality inks, coatings, and colorants, is tackling this challenge head-on with some innovative solutions.

There is a dual aspect of food contact printing: printing directly onto food items and printing on the interior of packaging that comes into contact with food. With increasing demand for personalised and branded food items, the need for safe, direct food contact inks has never been more critical. Sun Chemical's development of edible inks and coatings opens the door for reducing plastic use in packaging by replacing plastic liners with food-safe, water-based inks and coatings.

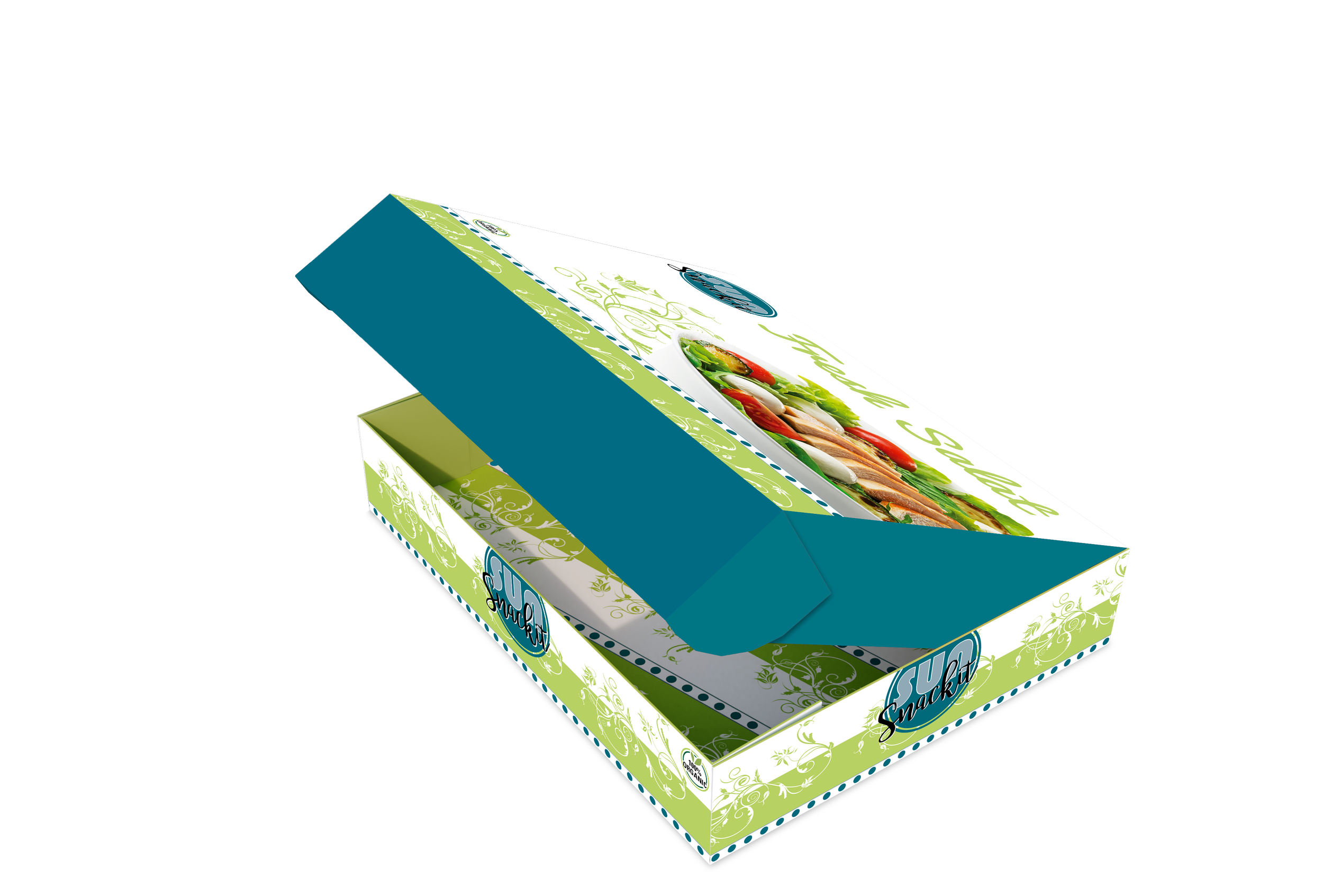

Simon presented two examples to illustrate the potential of these innovations. The first involved redesigning packaging (for example a sandwich packet) to eliminate plastic windows and liners, replacing them with a dehaze varnish on a paper substrate to maintain transparency without plastic. The second example discussed a collaboration with Whitaker's Chocolate, where Sun Chemical helped develop a packaging solution that significantly reduced plastic content by replacing the plastic trays with a coating that was able to come into direct contact with the chocolates, which is a huge step towards fully recyclable, paper-based packaging.

Despite the advancements, Simon Daplyn acknowledged that paper cannot entirely replace plastic in all packaging applications due to the specific benefits plastic offers. However, the integration of direct food contact inks means companies can take a significant step towards creating more sustainable, recyclable packaging options where feasible.

More information on Sun Chemical

More information on Edible Inks for Direct Food Printing