Beyond the Barcode: How Connected Packaging is Redefining Print, Technology and Consumer Trust

This article is inspired by a recent podcast interview with Stefan Casey of io.tt. To check out the podcast, click here.

When Stefan Casey describes himself as a “jack of all trades”, it is not false modesty. From sketching portraits in Paris to digitalising KitKat wrappers in York, his eclectic career has carried him through hospitality, design, packaging, advertising, and FMCG innovation. Now, as Head of Ecosystem at io.tt, a connected packaging business launched out of agency SharpEnd, Casey has a new mission: persuading brands and retailers that packaging is no longer just a container but a digital interface, a storyteller, and in some cases, a lifesaver.

Casey embodies the collision of creativity and technology. He began as a designer, schooled in the days when QuarkXPress and clip-art were upending the publishing trade. Early exposure to automation—he recalls the hundreds of jobs displaced by software plug-ins—taught him that technological disruption is cyclical. “History repeats itself,” he says. “Technology does impact, but it also creates new hubs of excellence.”

That lesson stayed with him as he moved from the printing halls of Trinity Mirror to the brand boardrooms of KPMG Nunwood, then into academia at the Faraday Institute, and finally to Nestlé, where he helped spearhead digital transformation projects such as personalised KitKat bars and paper-based chocolate wrappers. Each role sharpened his conviction that innovation is not a department but a mindset.

From Chocolate Bars to Codes That Speak

At Nestlé’s confectionery R&D hub, Casey was an outlier—“a creative in a world of scientists”. But it was here he discovered the potential of digital print and the early seeds of what is now called connected packaging. He recalls collaborations with HP that enabled consumers to print their faces on chocolate bars, long before “personalisation” became marketing jargon.

That experimentation also spilled into sustainability. Nestlé’s shift of KitKat into paper wrappers and Quality Street into recyclable packs are now commonplace industry moves. At the time they were radical. “Plastic can be fantastic,” Casey cautions, “but only if it’s fit for purpose. The real lesson is that design, materials and print must be considered together, at the start of the process, not tacked on later.”

The emphasis on early collaboration is a recurring theme. Whether curating partners for a new packaging line at Nestlé or orchestrating a network of technology providers today, Casey argues that efficiency is found not in silos but in ecosystems. “Common sense should be on every CV,” he quips. “Bring everyone into the room at the beginning—designers, printers, coders, brand managers—and you save money as well as time.”

Connected Packaging: Beyond the QR Code

At io.tt, the commercial expression of this philosophy is “connected packaging”: enabling everyday packs, labels and products to deliver digital experiences via scannable technologies such as QR codes or NFC.

The pandemic normalised QR codes for consumers everywhere, but according to Casey, many brands still squander the opportunity. Too often, a scan leads to a broken link or a corporate home page. For Casey, this is worse than doing nothing—it actively erodes trust.

Done well, however, connected packaging can enrich consumer experience and supply-chain efficiency alike. He cites recent projects:

· Boots, which uses connected guides to replace unreadable multilingual leaflets in medical devices with digital instructions and videos. The result: less frustration for patients, and improved safety with reduce printing costs with the potential as a future replacement for less regulated products. [https://sharpend.com/work/boots]

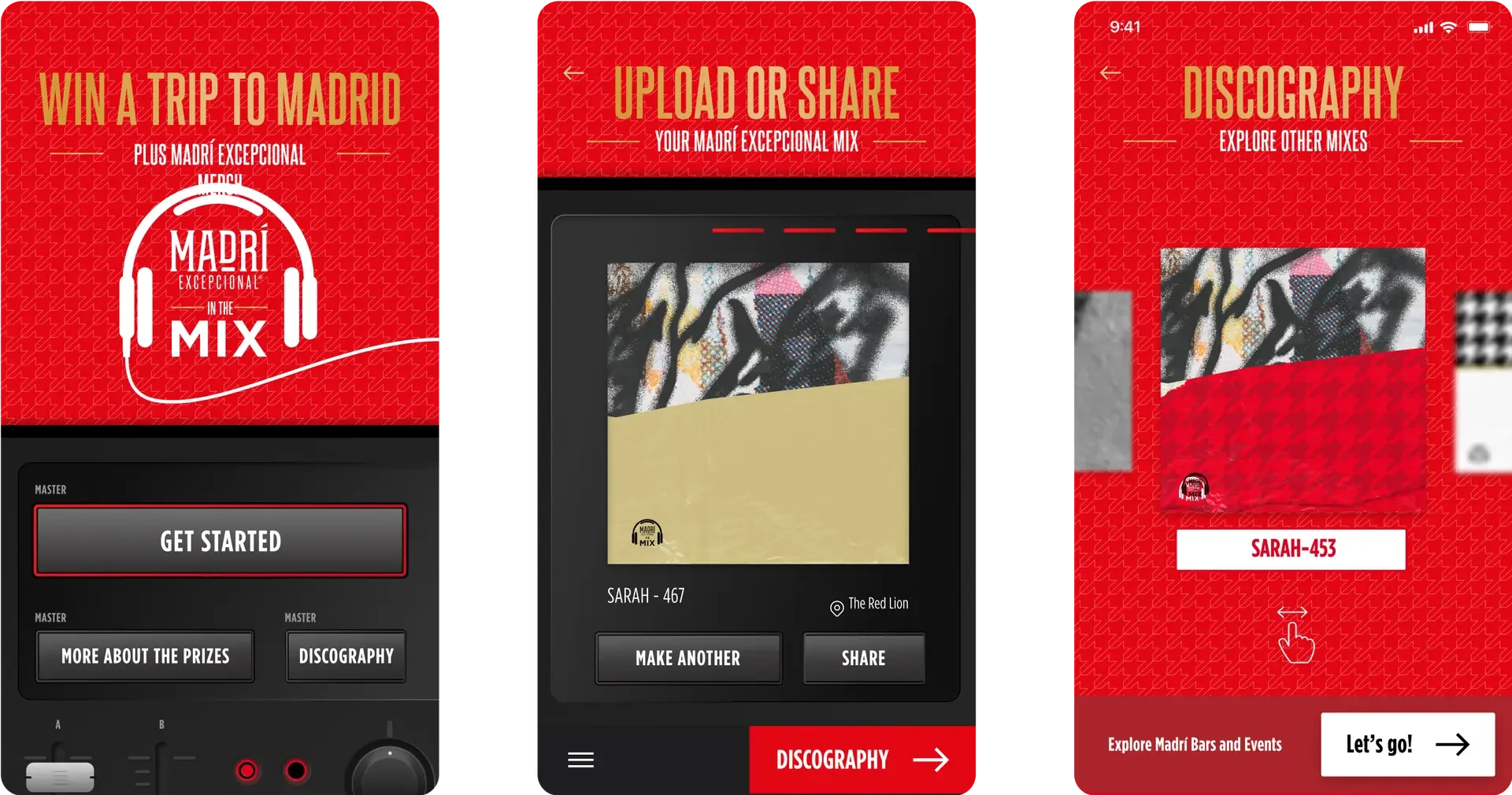

· Madri beer, which integrates gamification, pub-finder services, and social media activations directly into the glass and label. [https://sharpend.com/work/madri]

· Madri Beer, BRAND NEW – Launch of its interactive Music Competition where you can create your own beat! _pictures only and attached for you Marcus

· Moose Knuckles, a luxury fashion brand that turned regulatory digital product passports into a platform for storytelling and brand experience. [https://sharpend.com/work/moose-knuckles]

Such applications are no longer gimmicks. “You can literally save lives with this technology,” Casey insists, pointing to allergens and dosage instructions that can be updated dynamically.

The Buckets of Change

Asked to identify the biggest forces shaping packaging and print, Casey divides them into “buckets”.

· The environmental bucket: sustainability is both a regulatory stick and a reputational necessity. Extended producer responsibility (EPR) laws, Digital Product Passports under ESPR and anti-greenwashing rules are driving brands to prove, not just claim, their eco-credentials. Yet consumers expect such efforts as a baseline, not a differentiator. “Citizens expect it,” he says.

· The innovation bucket: material and commercial innovation are under strain as R&D budgets shrink. Over-reliance on AI modelling, without real-world testing, risks eroding expertise. “Talent is escaping,” Casey warns.

· The fit-for-purpose bucket: one size does not fit all. Accessibility features, clear allergen labelling, and appropriate materials are too often stripped away to save pennies.

· The digital bucket: rapid advances in digital print, coding and AI offer scale, speed and personalisation never before possible. But adoption depends on cultural change. “Factories don’t want to change—they just want to churn out volume. That has to shift.”

Print’s Digital Dividend

For the print industry, connected packaging could be the long-awaited catalyst for digital print adoption. After decades of forecasts that digital would supplant analogue, Casey believes the tipping point may finally be here. Personalised limited runs, seasonal editions and supply-chain responsiveness play directly to digital’s strengths.

Moreover, digital print dovetails with the demand for unique identifiers—whether for consumer engagement, grey-market security, or compliance with EU rules mandating digital product passports. “The excuses are gone,” he says. “The tech is there. Use it!”

Collaboration, or the Lack Thereof

If technology is available, why the slow adoption? Casey blames mindset. Internal turf wars—marketing vs. packaging, IT vs. R&D—sap progress. “Stop competing internally and start collaborating externally,” he urges. His own title, Head of Ecosystem, reflects that ambition: building trusted constellations of partners who can move faster together.

This extends to industry-wide initiatives. Casey is a founding supporter of the Manifesto for More Sustainable Print, a collaborative platform bringing competitors together to share knowledge on inks, coatings and chemicals. Too much attention, he argues, is paid to materials alone. “What worries me are the chemicals we’re putting on packs, entering waterways. We need education, transparency and shared standards.”

The Road Ahead

Looking forward, Casey is excited—and candidly apprehensive—about artificial intelligence. “AI will take jobs, hundreds of thousands,” he predicts. But it will also create new roles and finally enable long-deferred ideas to scale. “Every industry is touched—medical, logistics, FMCG. The best will prevail.”

For print and packaging, the promise is more immediate: dynamic packs that update in real time, campaigns that adapt regionally overnight, and safety systems that prevent the next allergen scandal. But realising this requires cultural transformation as much as technological investment.

His message to brands, retailers and printers is blunt: embrace collaboration, plan early, and treat packaging as part of the product, not an afterthought. “Packaging is the glue that binds,” he repeats, “and connected packaging is the glue that binds everything—design, print, supply chain, data, and the consumer.” In other words: ignore the glue at your peril.