For Hymmen, Ricoh and the Wood-based panel industry, Saturn offers new planetary possibilities in décor print.

Carsten Brinkmeyer, Hymmen

Hymmen and Ricoh are both well-known names. Hymmen is famous for technology for decorative surfaces, in particular floors, and Ricoh is famous in the development of digital printing technology. In this interview, we talk to Carsten Brinkmeyer of Hymmen and Richard Darling of Ricoh about their collaborative development work with the creation of Saturn, a new water-based inkjet-printing device for digital laminate paper printing for floors.

Carsten, So Hymmen has created a new inkjet printing machine, what has driven you to innovate once again?

Market demand. Decorative surfaces must be produced quickly and flexibly in the right quality and at a reasonable price. For over a decade, attempts have been made to achieve these goals in industrial digital printing on decorative paper with water-based inks – so far without success.

One of the main reasons for this was that neither the machine and plant manufacturers nor the printhead manufacturers applied their respective expertise together to foster industrial development. This has now changed: thanks to the development partnership between Hymmen and Ricoh, manufacturers of digitally printed decorative paper now have a strong technology team at their side.

Richard, explain how Ricoh has joined with Hymmen?

Richard Darling, Ricoh Europe

Hymmen already had the Jupiter, a single pass UV Inkjet printer for décor and flooring. If you recall, this won the Great Innovations Award at InPrint 2014. It sells reasonably well but was only for inkjet printing with UV inks, constrained by the Xaar printhead technology. Xaar technology had many advantages such as recirculation but no capability for water-based inks and water-based is a specific need of this industry to fit in with pre and post processes. Ricoh has printheads for water-based inks, and also recirculation. The attractive part to Hymmen was that not only were we providing the inkjet printhead components, but Ricoh also formulates and produces inks and itself builds water-based printers. The two companies formed a working collaboration to qualify what wood décor operators need and to build something together from ink, printhead and software through to manufacturing.

So is partnership and experience with the Saturn project core to its success?

Yes. Hymmen have decades of heritage in the wood-décor industry and already had print experience with Jupiter going back to 2008. They were familiar with the challenges of applying inkjet in the flooring industry. But they knew they didn’t have exactly the right system. What many industry specialists don’t always have is the necessary spare funds to take an innovation to market. One of Ricoh’s key contributions to the project is the initial funding but there are other elements. The shared aim is to introduce standardised, de-centralised digital printing to wood décor globally. For that, we need efficient, effective technical support. Ricoh has an infrastructure of service engineering that could support local demand but on a global basis.

Carsten, what in your view are the benefits of working with a technology partner such as Ricoh?

Ricoh is a company with branches around the world and has over 40 years of printhead production experience. The Ricoh industrial printing group specializes in and is strategically focused on inkjet printing. The core technology comprises printheads with a metal nozzle plate, which are used with a wide range of liquids. Ricoh brings the printhead technology for water-based inks into the development partnership. The Colorgate software and the ink chemistry are also contributed by Ricoh. Thousands of service employees are already available around the clock worldwide to provide customer support for digital printing equipment.

The RICOH/Hymmen partnership boasts in-depth expertise in digital printing technology, the markets, and process management. With a focus on water-based digital printing for decorative paper, the result of the cooperation between the two companies is set to be a product to offer “a plug-and-play industrial inkjet solution for the wood-based materials industry.”

Richard, why has Ricoh chosen to work with Hymmen?

Hymmen is a great partner firstly because we share the same vision. We think that the market must change from a somewhat inflexible centralised print supply structure to a decentralised, in-plant, versatile decoration system. The need of wood décor producers is clear. This could eventually develop into a managed services business with existing print suppliers or by Ricoh but decorating on-demand at the point of board production is logical. This is an inevitable change that Saturn can facilitate.

Choosing a partner who already has excellent connections to a market is a critical element for success. Hymmen understands its market and the whole process of production far better than we do. They already have experience of the integration of inkjet with Jupiter and introducing inkjet to wood décor so this partnership has the right blend to develop and launch Saturn quickly into the market. Neither party had all the answers at the start. We learned and continue to learn from each other and together. We have to be prepared to be uncomfortable, to challenge what we think we know and to explore with openness with concern only that we come to the right outcome. Hymmen’s owner, Dr Rene Pankoke himself is open, methodical and has been committed to inkjet in wood décor for many years.

Digital technology has been a long-term thing for Hymmen, a family business since the 1892. Hymmen is taking a long-term whole generation view as a private company. Ricoh is also thinking long term and strategically and as a PLC I think this is a refreshing approach. We have a great team on the Saturn project including Michael Laege Project Manager from Hymmen, Carsten and myself but also Changlong Sun from Ricoh who has been involved from the ink qualification side. We respect one another’s areas of expertise.

Carsten, Explain a little more of the digital background of Hymmen

For more than a decade, Hymmen has been a leading specialist in digital printing in the wood-based materials industry. The more than 40 single-pass machines sold deliver top performance all over the world, reliably maintained by a skilled digital printing team. Extensive process knowledge, automatic colour calibration, and full automation are some of the factors that ensure sustainable production at an industrial level. Repeated investments by individual customers attest to the technological performance and profitability of the Hymmen systems.

How has engineering evolved to make Saturn a reality?

Major challenges in the development of the complex single-pass digital printing technology have already been mastered. Hymmen already offers a very solid technology for printing decorative paper with UV-curable inks. However, there are applications where the product cannot be built as required for UV-curable inks. This is where water-based inks come into their own. Hymmen's know-how and experience in the manufacture and finishing of wood surfaces as well as its contacts in the flooring and furniture industry make the company an ideal partner for a printhead manufacturer with expertise in water-based ink.

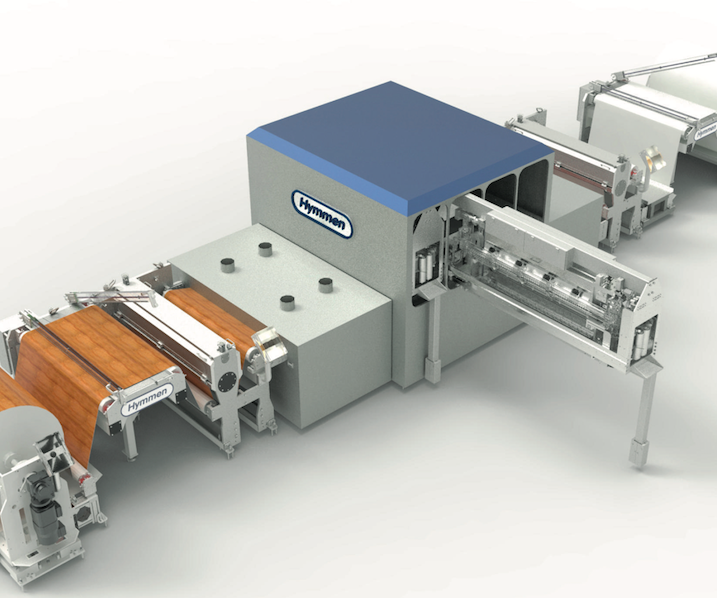

Saturn by Hymmen in partnership with Ricoh Europe

Is Saturn a stand-alone machine or can it be easily integrated?

SATURN can be integrated into customers' existing production processes. It is a standard machine that offers printheads, ink, and printing at the desired resolution for an affordable price. SATURN guarantees efficient decentralized production at the expected quality level.

The SATURN Digital Printing Line is a breakthrough in the production of digitally printed decorative paper. This system differs from the existing water-based printing solutions in that it is decentralized, more flexible in terms of design for both small and large batches, and not primarily focused on replacing analogue technologies with digital ones. SATURN ensures minimal storage of decorative papers through just-in-time production. The entire process in the new facility is much easier than with existing decorative printing equipment. Drying the inks is easier and the printing process is more stable and reliable. Finally, SATURN requires a lower investment volume.

Does Saturn also introduce new possibilities in terms of the supply chain?

Yes. With SATURN decorative surface printing is approached in a new way. The dynamic of the supply chain is completely changed. While typically décor papers were manufactured in centralized locations before further processing in impregnation facilities, now the local production of the décor paper is possible. Batch-production meets the customers needs quickly, on-demand and skips the logistical overhead such as shipping and warehousing.

As shown above, Hymmen and Ricoh bring not only technological innovation in print forward. The companies realized that they also need to address the critical elements to improve the supply chain significantly. They need to make fundamental changes to the way décor suppliers have worked in the past. Improved time to market, quality output and reduced inventory – this is what the on-location printing just in time with the SATURN Digital Printing Line ensures. In other words: Now the flexibility of digital printing reaches also the decentralized production sites.

Owing to the partnership between two established companies in the digital printing market and their combined expertise, Hymmen and RICOH are your ideal partners for tomorrow’s water-based digital printing and we are both excited at its potential.

Finally, you showed Saturn to a select group of potential customers at Ligna. What was your feedback and are there any BETA sites that people could visit?

The feedback during the Ligna presentation was stunning. All of the people we spoke to agreed, that decentralised printing is a must to make the benefits of digital printing available to the board manufacturers. The SATURN will meet all the demands and we got many requests from companies that like to be the first to begin using the system and benefit from its capability. We will have a BETA machine ready in 1400mm by end of this year. After 1-2 month internal testing we are then happy to do customer trials beginning of March 2020.

For more information:

Carsten Brinkmeyer, Hymmen C.Brinkmeyer@hymmen.com

Richard Darling, Ricoh Europe richard.darling@ricoh-europe.com