Lighting Up New Possibilities: How Excelitas’ Expansive Product Range Transforms Print Curing

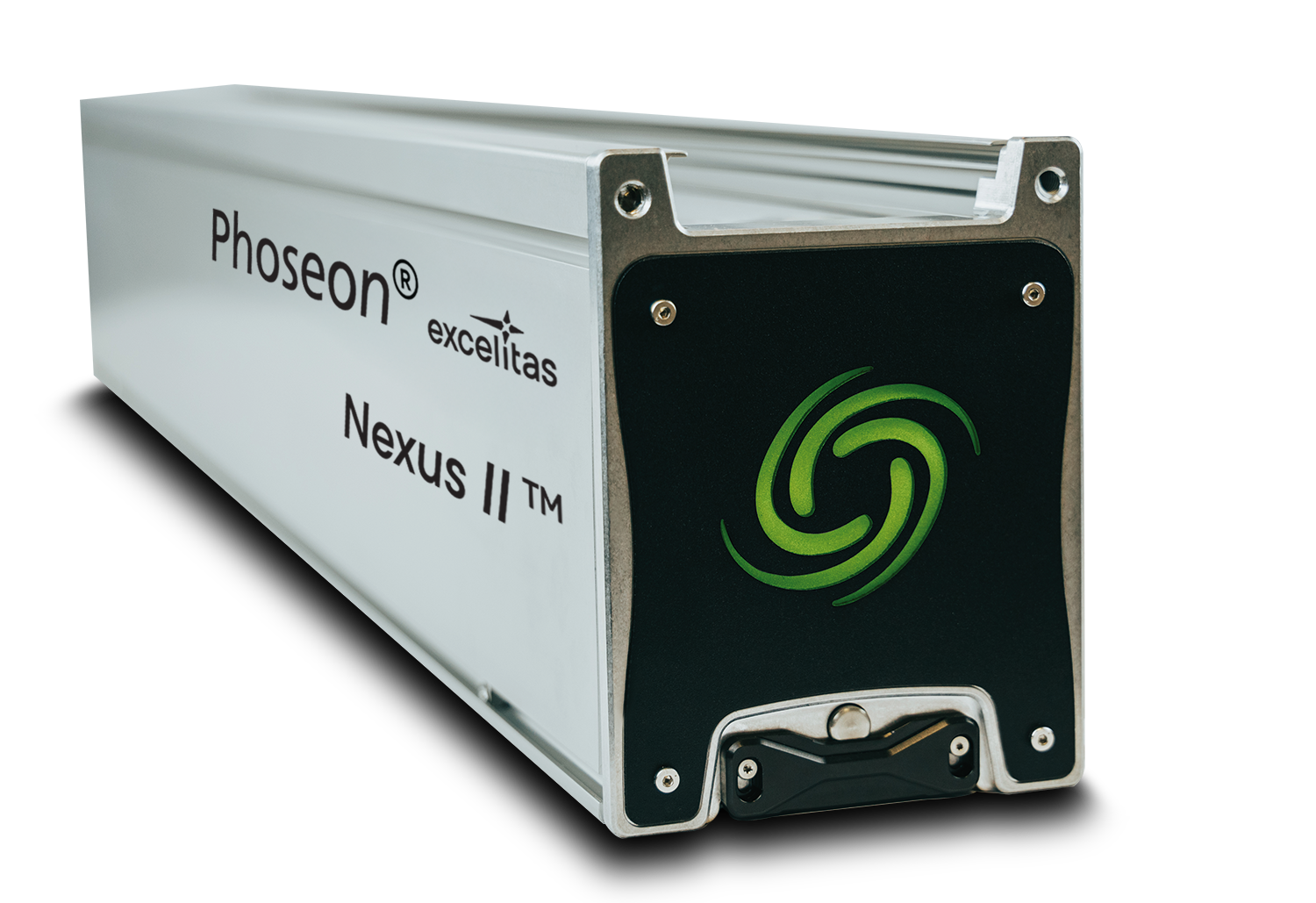

Excelitas launch the Phoseon Nexus II UV LED System at LabelExpo this month

This article is inspired by a recent podcast interview with Rob Karsten of Excelitas in advance of LabelExpo in Barcelona. You can take a listen here.

Excelitas is not merely selling curing systems—it is reshaping what’s possible for printers and converters. By uniting UV, LED, infrared, excimer, and thermal technologies under one roof, the company has built a portfolio capable of addressing almost any curing requirement in the print and coatings industries. For customers, that means a single partner can now deliver tailored, hybrid solutions that boost performance, cut energy costs, and open up entirely new production possibilities.

When global photonics specialist Excelitas acquired Phoseon Technology nearly three years ago, it was more than corporate consolidation. It was a calculated step towards becoming the most complete provider in the market, reinforced by the later addition of Heraeus Noblelight. These moves created the Advanced Lighting Systems division—a team equipped not only with a broad array of UV and other curing technologies, but with the expertise to combine them into integrated, market-focused solutions.

A wider canvas

This broadening of scope matters because the print industry is no longer defined by neat technological silos. UV printing, while a well-established niche, represents only a fraction of the global market. Much of the volume remains aqueous, a field in which Phoseon had little presence. “Now,” says Rob Karsten, EMEA Director for Advanced Lighting Systems, “we have world-class solutions for aqueous too. And some customers are mixing technologies on the same press—aqueous coatings at one stage, UV inkjet at another, and perhaps a third curing process at the end. You could have three different curing technologies on the same platform, all from one supplier.”

Integrating these capabilities has not been trivial. Different legacy systems—CRM, manufacturing, R&D processes—had to be harmonised. More importantly, teams with deep but specialised expertise needed to learn each other’s disciplines. Excelitas has leaned heavily on Noblelight’s infrared veterans to advise its UV-centric sales force, while sharing LED and excimer expertise in return. “No question is a stupid question,” Karsten says. “We want our people to be confident enough to ask, so that when we’re in front of a customer, we can offer the best-fit solution, even if it’s outside our original spheres of specialism.”

The label market’s resilience

This year’s LabelExpo in Barcelona will be the first in that city, and Karsten’s team sees it as an opportunity to showcase the depth of the expanded portfolio from Excelitas. “We’ll have our UV LED products, the Noblelight flexo curing systems, and AMBA spare bulbs that remain a mainstay in the flexo market,” he says. The headline will be the launch of Nexus II, the latest evolution of Excelitas’ UV LED curing platform.

The upgrade is not cosmetic. Nexus II brings new form factors, enhanced functionality, and more sophisticated data integration for predictive maintenance and Industry 4.0 compatibility. It is intended to appeal to converters and OEMs alike, not least because the label market—despite broader economic uncertainty—remains one of print’s most robust segments.

“Almost everything has a label,” Karsten observes. Regulation on language, content, and safety information ensures demand rarely falls. Investment cycles can slow, but that often leads converters to seek performance gains from existing equipment rather than replacing it outright. Here, UV LED conversion has become a favoured tactic. Replacing traditional arc-lamp curing with UV LED can deliver both speed improvements—up to 20% more throughput in some cases—and substantial energy savings.

Though energy costs have retreated from their recent peaks, they remain high enough to keep efficiency at the top of converters’ agendas. “Margins in labels are tight,” Karsten notes. “You have to make a lot of labels to make a lot of money. So anything that reduces running costs and boosts yield has an impact.”

Hybrid thinking

The label industry is no stranger to technological adaptation. Hybrid presses—combining flexo and inkjet—are now commonplace, driven by the steady improvement of inkjet quality and speed. A decade ago, inkjet was scarcely visible at LabelExpo; today, it is a dominant presence, whether as standalone single-pass presses or as retrofitted engines bolted onto flexo frames.

Excelitas is involved at multiple points in this chain. OEMs can integrate its UV and other curing systems into new builds; converters can retrofit existing lines; and in both cases, the choice of curing technology can be tuned to the application. For high-coverage graphics on short runs, UV LED offers instant start-up, cool operation, and lower maintenance. For heavy laydowns or specialty coatings, infrared or excimer curing may be added to the mix.

This flexibility is not merely technical—it’s strategic. By offering multiple, complementary curing methods from a single supplier, Excelitas positions itself as a partner in process optimisation rather than a vendor of discrete components. That matters in a market where converters are seeking ways to differentiate themselves without over-extending capital budgets.

From technology to solutions

Karsten’s remit now spans printing and wood-coating solutions, a reflection of Excelitas’ push into adjacent markets. The underlying drivers—efficiency, quality, sustainability—are consistent across these sectors. In each, Excelitas can propose a tailored blend of UV, LED, infrared, excimer, and other curing technologies, backed by application testing in dedicated demonstration centres in Germany and elsewhere.

The move towards a solutions-based model is partly about revenue diversification, but it is also about resilience. As the print industry becomes more project-driven and less reliant on long-run commodity work, suppliers must be agile enough to serve a broader base of customers with varying needs.

Barcelona and beyond

At LabelExpo, Excelitas expects a busy schedule of meetings with both existing customers and new prospects. The company will use the event to underline three themes: the breadth of its curing technology portfolio, the benefits of upgrading existing equipment to UV LED or hybrid systems, and the integration of its products into Industry 4.0-ready workflows.

In practical terms, that means live demonstrations of Nexus II’s enhanced monitoring and predictive maintenance capabilities, side-by-side comparisons of UV LED and conventional curing performance, and discussions on how to retrofit curing solutions to maximise ROI on existing presses.

For Karsten, the show is also an opportunity to reinforce Excelitas’ role as an innovation partner. “We’re there to talk about applications, to see where we can help people do a better job with what they’ve got,” he says. The message is that investment in curing technology—whether UV LED, infrared, or otherwise—can be both a performance booster and a cost-saver, with payback measured in months rather than years.

The long view

Photonics may seem far removed from the daily realities of label printing, but in curing technology, the two are inseparable. The physics of light—its generation, control, and application—is what allows inks and coatings to dry instantly, for presses to run faster, and for converters to reduce waste. Excelitas’ strategy is to be the most complete and most adaptable supplier in this space, capable of serving a market that is itself becoming more diverse and demanding.

As run lengths shorten, product lifecycles shrink, and regulatory requirements proliferate, converters will need to be able to change processes quickly and economically. The suppliers who can help them do that—without forcing them into narrow technological cul-de-sacs—will be the ones who endure.

Excelitas, with its expanded Advanced Lighting division and comprehensive range of UV, LED, infrared, excimer, and thermal solutions, is betting that breadth, depth, and integration will be the winning combination. In Barcelona, the company will have the chance to prove it.