The Factory of the Future - Rob Karsten, Excelitas

In manufacturing, the concept of the "factory of the future" is becoming a focal point for industry leaders. This topic was discussed in a recent presentation given by Rob Karstens, Sales Director EMEA at Phoseon, part of Excelitas Technologies at FuturePrint TECH’s Digital Print for Manufacturing event. In his talk, Rob discussed the move towards fully automated, or "dark," factories, and the role of digital technologies.

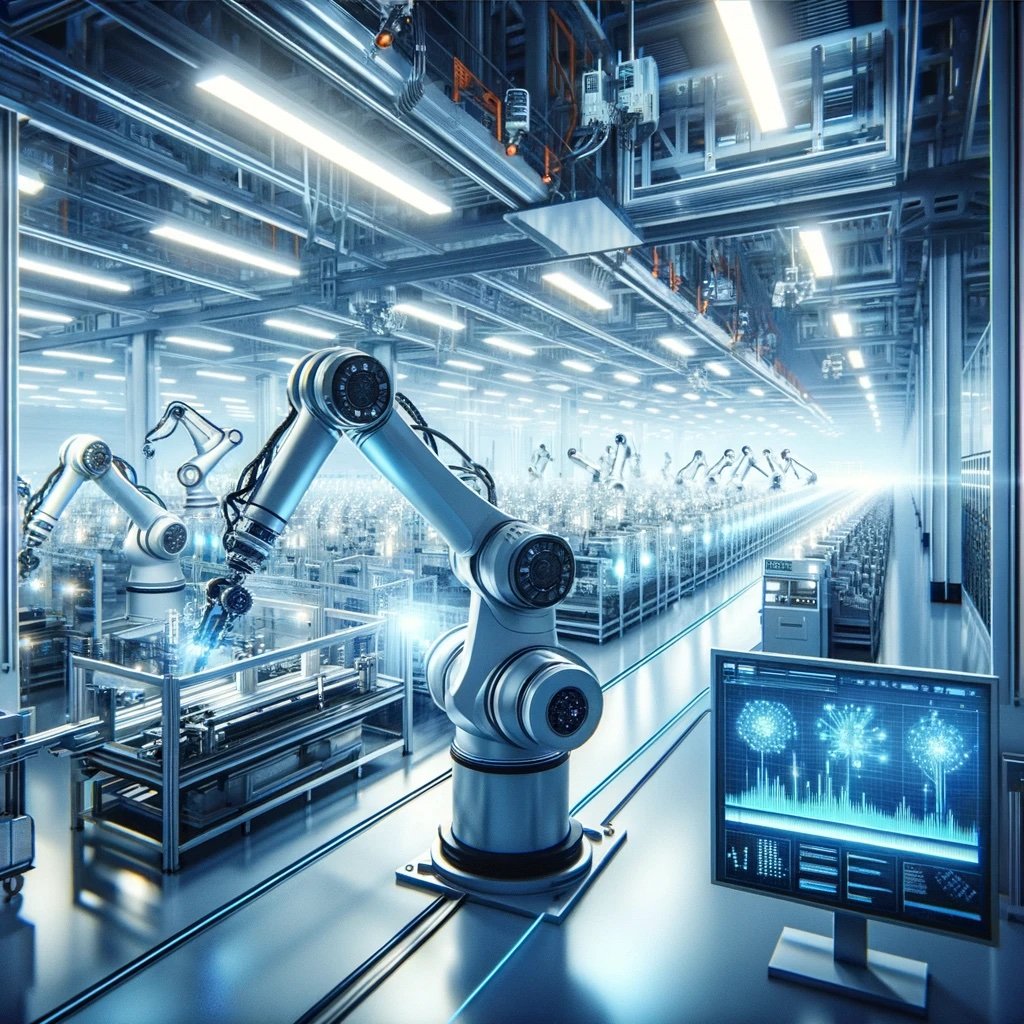

AI generated image depicts a factory of the future without people

The Industrial Revolution laid the groundwork for monumental advances in manufacturing efficiency and productivity. Beginning with the introduction of the steam engine and moving through the era of automation and electronics, each stage has moved the industry forward. Today, we are anticipating the next revolutionary jump: the dark factory. These facilities, theoretically devoid of humans, could operate autonomously, only powered by robotics and advanced digital systems.

While the strict definition of a dark factory - a manufacturing plant that operates without any human presence - might not be fully realised yet, examples like Intel's facility in Oregon come close. Here, robots handle most tasks, with minimal human intervention, showing just what's possible with substantial investment in automation technologies. Despite the attraction of fully dark factories, the current trend leans more towards automation that complements rather than replaces human labour, such as is used by companies like Amazon and Danish Crown. These focus on using robotics for efficiency while maintaining a human workforce for tasks that require a level of intuition and decision-making robots can't yet replicate.

A driving force towards more automated manufacturing environments is the adoption of digital technologies, such as LED technology for example. Phoseon illustrates the potential of LED technology in the factory of the future with technologies like the Phoseon Link, a cloud-based platform that facilitates continuous monitoring of LED light sources, providing users with real-time feedback on critical operational parameters such as lamp uptime, press uptime, and material utilisation. This level of monitoring means that production processes are more efficient more predictable and manageable, leading to significant improvements in throughput and quality. Complementing the Phoseon Link is another solution offered by Phoseon Technology called Valid Cure. This software technology assures the effectiveness and consistency of LED curing processes. Valid Cure works by individually tailoring the curing process to specific materials and operational requirements, which optimises the curing performance for each application. This customisation is achieved through advanced algorithms that adjust the intensity and duration of LED exposure based on real-time feedback and predefined material properties. As a result, Valid Cure calibrates each curing cycle to achieve optimal results, reducing waste and enhancing the quality of the final product.

While the concept of fully dark factories may still be on the horizon, it is technologies like these that are laying the groundwork for a more efficient, sustainable, and innovative manufacturing landscape. Check out this link for more information on Phoseon Technologies and Excelitas Technologies