Why Total UV Power is Important for UV LED Curing

What is total UV power?

When it comes to performance parameters, it’s important to measure both peak irradiance (measured in watts per square centimeter) and energy density (measured in Joules per square centimeter). Both peak irradiance and energy density contribute to the total power of the UV LED curing system. However, not all LED lamps with the same peak irradiance have the same total curing power. LED lamps with low energy density often have focusing optics that artificially bump up peak irradiance. Energy density is the key to ensuring adhesion and cure at high speeds.

Today, many UV formulations have been optimized for UV LED sources, and a higher peak irradiance often is no longer necessary. Research reveals that in many cases, excessive irradiance can negatively affect or hamper proper curing. Sometimes turning down the irradiance and providing more energy density is the way to improve cure for faster line speeds. The light source’s proximity to the substrate is important because irradiance decreases with distance. Manufactures can use optics to manipulate a higher irradiance over a greater distance. With or without optics, vendors compensate for this with different LED arrays, optical elements, or a combination of both.

Energy density is a factor of the output of the engineered light source, the number of UV sources, and the exposure time. In other words, increasing the irradiance, slowing the line speed, or adding more or wider lamps will all increase energy density for a given installation. It is important to understand that not all products with the same irradiance deliver the same energy density.

Energy density also is impacted by the speed at which the substrate or part passes under the lamp; or conversely the lamp passes over the substrate or part. Theoretically, if a material is curing sufficiently at 50m/min, then increasing the speed to 100m/ min while doubling the irradiance will result in delivery of twice the energy density, which should cure the material sufficiently. Increasing the irradiance of a given lamp will increase the energy density by the same percentage. The cure surface is subsequently exposed to the same amount of dose. Unfortunately, most real-world applications are never perfect, and the chemistry doesn’t always scale up according to theoretical models of UV output.

Some materials don’t cure faster when additional irradiance is provided. Increasing the belt speed to 100m/min sometimes requires double the dwell time, not an increase in irradiance.

Total Power Output

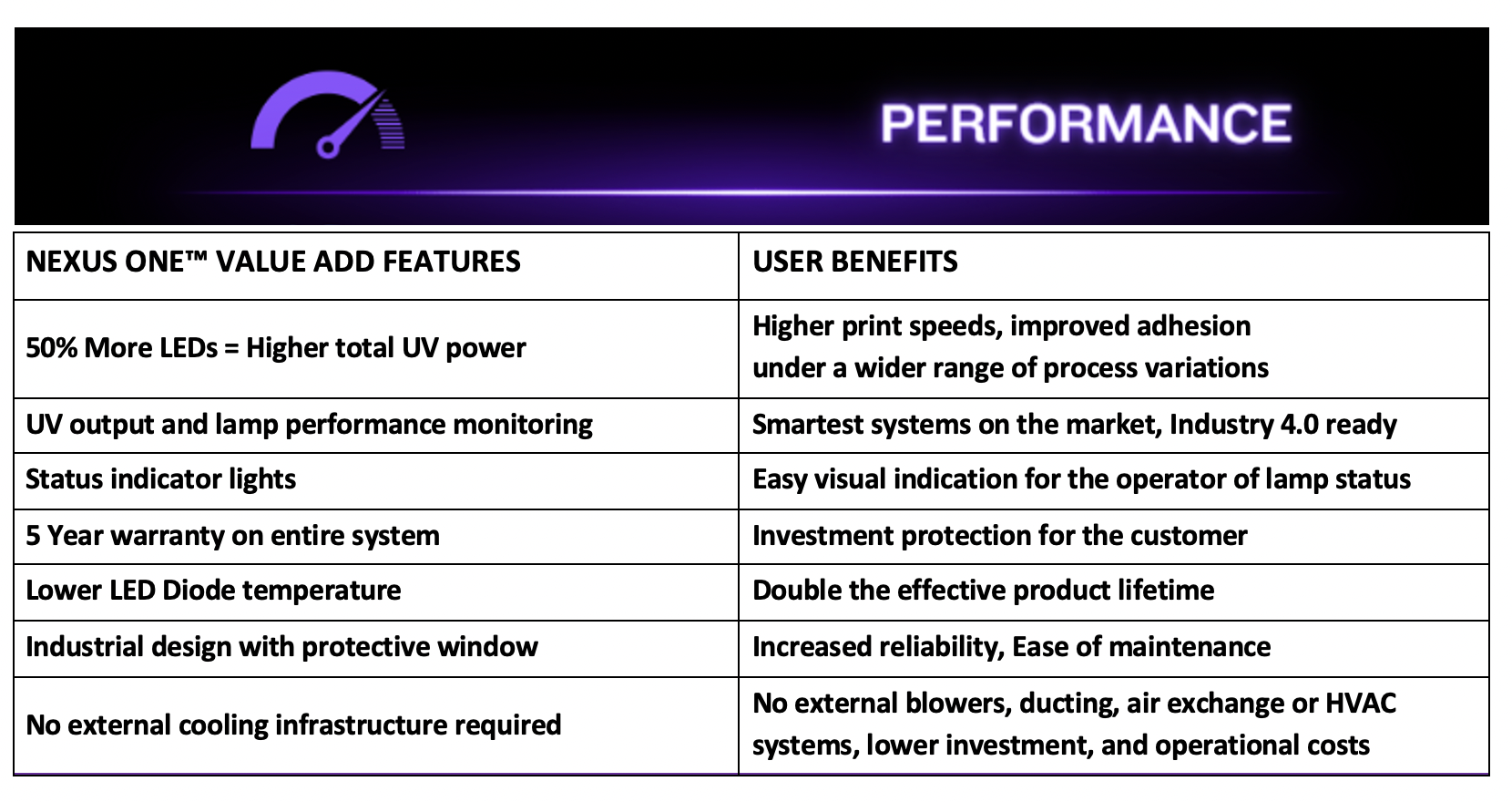

With 50% more LEDs, Phoseon Nexus ONE products have measured significantly higher total power output compared to the other systems on the market. Nexus One premium UV LED curing lamps deliver higher total power that delivers unmatched

performance and increased print speeds up to 220 m/min and 65 Watts per LED array segment. By enabling excellent adhesion for quality applications at faster press speeds, the Nexus ONE is superior to competitive products on the market.