XAAR’S HIGH-VISCOSITY INKJET COLLABORATION DELIVERS FAST TRACK INNOVATION FOR DÉCOR APPLICATION

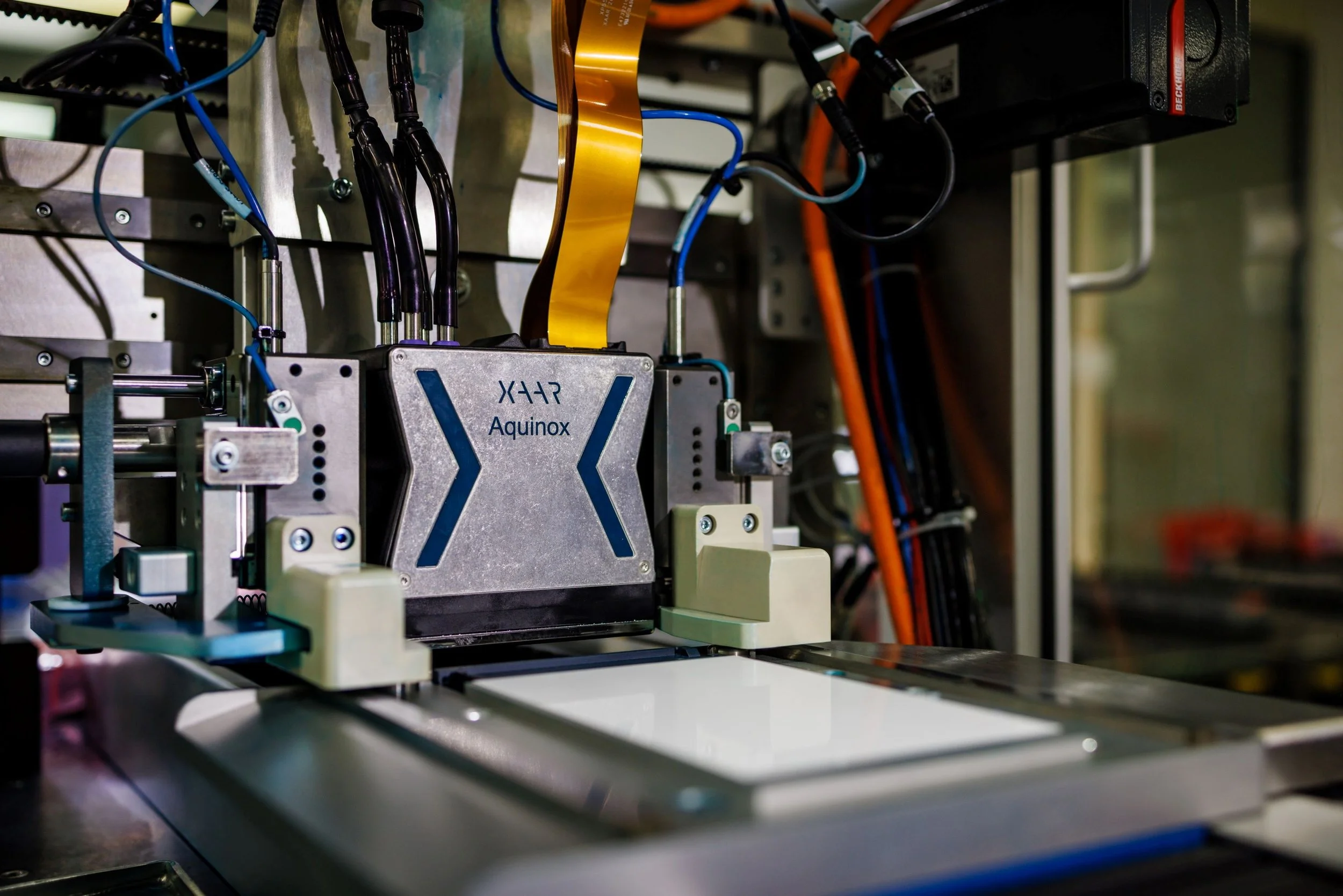

Xaar’s Aquinox printhead and newly enhanced fluid development process has accelerated innovation in printing onto porous wood substrates used in decorative interior applications. The project showcases how high-viscosity, water-based inks can transform cost-effective wood materials into premium, high-value décor elements for furniture, wall cladding, and other architectural design elements.

The collaboration with bespoke inkjet machinery manufacturer Inkatronic delivered exceptional print quality and reliability for printing onto the challenging substrates. Xaar’s newly enhanced inkjet fluid development process played a pivotal role in accelerating Inkatronic’s project timeline. Designed to remove traditional barriers to inkjet adoption, the process offers three flexible pathways –ranging from ready-to-use fluids with optimised waveforms to fully bespoke development support.

Inkatronic chose to work with Nazdar’s pre-approved high-viscosity water-based inks, leveraging Xaar’s in-house print trials and waveform expertise to validate performance on wood substrates in under a month. These inks were carefully formulated to remain on the surface of the highly absorbent material, helping to minimise ink wastage while ensuring strong visual definition and consistent coverage. This fast-track approach enabled Inkatronic to deliver high-quality samples quickly and confidently, without upfront investment.

Based in Austria, Inkatronic solves niche industrial challenges through in-house R&D and turnkey machine development. With a team of 20 and a strong focus on functional coatings, battery cell applications and digital printing, the company builds bespoke machines for a range of industrial applications.

“Working with Xaar has significantly accelerated our development timeline,” said Mikael Boedler, Business Development Lead at Inkatronic. “The Aquinox printhead’s ability to jet high viscosity fluids whilst maintaining sharp image quality at a 5mm throw distance, combined with reduced clogging and extended open time, has been a game-changer. Their pre-developed waveforms and close R&D support helped us move from testing to customer-ready samples in weeks, not months.”

“In industrial inkjet, reliability and sustainability are often at odds, but this collaboration proves they can go hand in hand and shows the reliability of inkjet on an industrial scale.”

The project also has key sustainability advantages. By switching from UV to water-based inks and printing in a single pass, Inkatronic has reduced energy consumption and eliminated the need for costly UV curing equipment. With further applications in additive manufacturing on the horizon, Inkatronic continues to push boundaries in digital inkjet integration, enabled both by Xaar’s technology and collaborative approach.

Commenting on the project Neil Cook, Head of Strategic Marketing at Xaar said, “We are delighted that Xaar is helping innovative companies such as Inkatronic open new applications for inkjet printing. Inkjet technologies are proving to be a game changer in many forms of manufacturing and this project proves that with our products and processes we can help accelerate development and innovation.”

Xaar and Inkatronic’s collaborative approach can be seen firsthand at the FuturePrint TECH: Industrial Print Technology for Advanced Manufacturing in Munich on 21st-22nd January.

Xaar’s Ultra High Viscosity Technology and printheads alongside Megnajet’s fluid management systems will demonstrate how inkjet is leading innovation in print, coating and manufacturing applications.